- PERSPEX or PLEXIGLASS is used in ultrasonic probes for the following reasons:

Protection of crystal and probe against wear

Improving the surface of the probe connection on the test surfaces

Correcting the angle of waves in the testing of complex parts

Making the right angle of the waves

Removing Dead Zone, Near Field when necessary

Use as a lens and focus waves

Protection of crystal and probe against wear

Considering the sensitivity of piezoelectric crystals and the frequency dependence of the probe on the thickness of the crystal, one of the protection methods is always the use of perspex. Other methods such as anti-wear parts are also used.

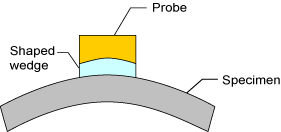

Improving the surface of the probe connection on the test surfaces:

The problems of using ultrasonic probes on rotating surfaces are solved by wearing perspex according to the tested surface.

Correcting the angle of the waves in the test of complex parts:

In complex parts, perspex parts are used to send waves to the desired position

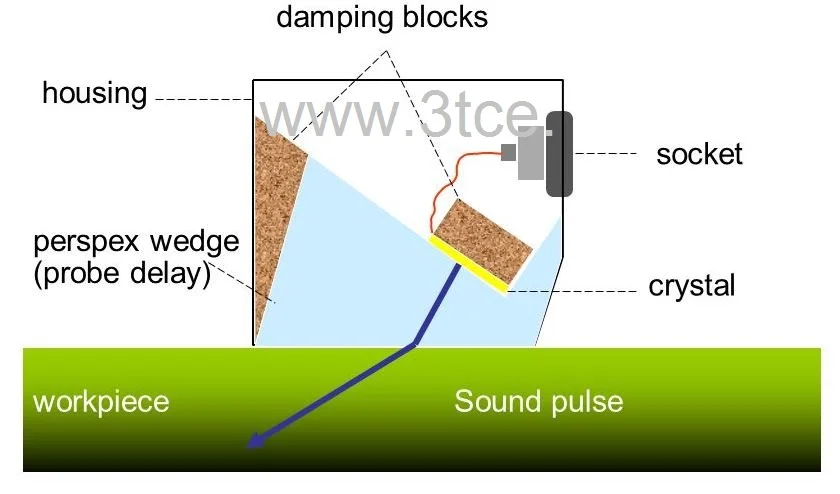

Making the right angle of the waves:

In making angular probes, one of the important points is to use the right material to get the desired angle. By considering Snell’s law, it can be understood that the speed of the material emitting the waves before entering the part determines the angle of the outgoing waves. For this reason, Perspex is one of the most widely used materials in the manufacture of probes, having the appropriate speed and sound propagation properties.

Removing Dead Zone, Near Field when necessary:

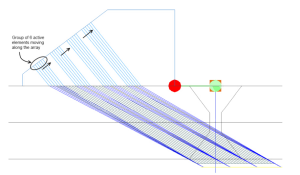

In partial testing, the presence of near field or dead zone probes leads to disturbance, it is possible to correct the transmitted waves by using perspex with appropriate thickness, which is also called delay-line probe.

Use as a lens and focus waves:

In order to focus the waves to focus the sound, you can use perspex with a suitable structure.